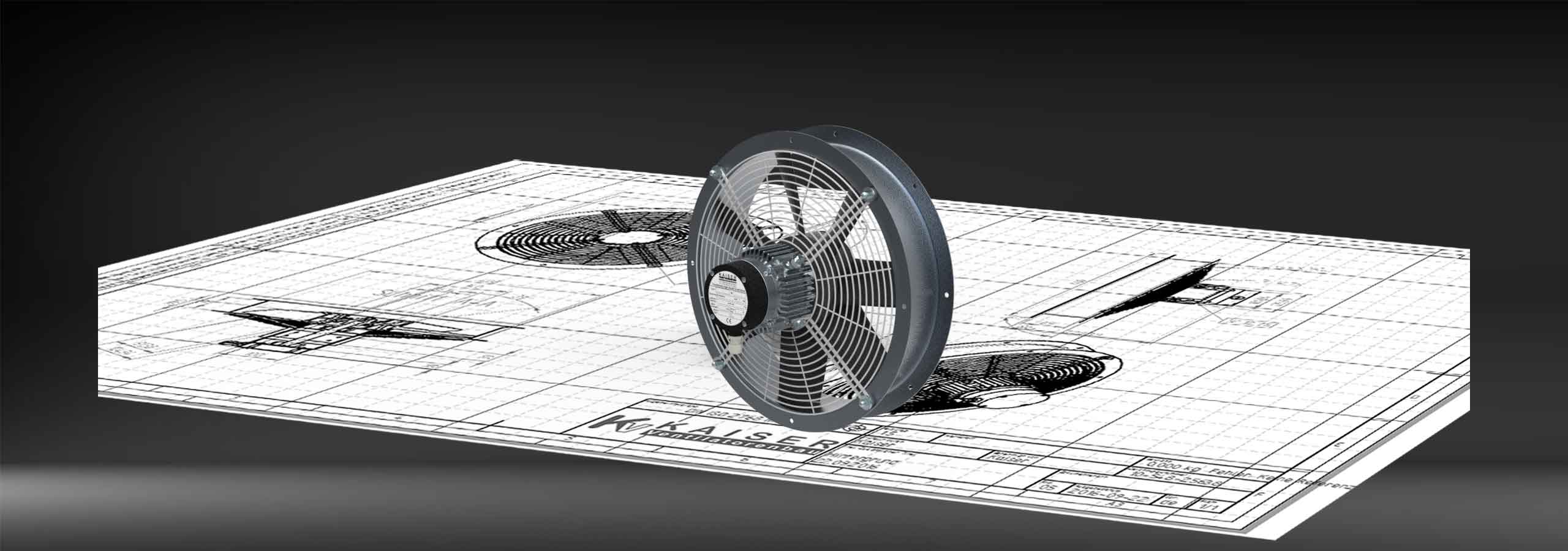

Axialventilatoren vom Hersteller - Auswahl bei Volumenstrom, Druck und Baugröße

Kaiser axial fans are available in axial design in type and shape in L, K, M, and G series. The products have the shape with 7 profiled plastic blades and a plastic hub, the larger products (shape and type M,G) offer a different shape of 7 profiled plastic blades. The pressure increases with blades with wing profile, contrary to the simple flat sheet metal blades, which can generate little pressure. The performance (flow and pressure) varies due to the nominal diameters, which are between 250-350 mm and 400-500 mm. All axial fan series are 100% speed controllable in power.

The fans (axial fans) are optimized for optimum efficiency in terms of volume and pressure.

Advantages at a glance:

- Kaiser axial ventilators are built as axial type and are controllable in the whole voltage range.

- Protection: They can be designed in protection type IP 44 or alternatively in protection type IP 54, tropical insulation is also possible. Protection type IP 56 is also possible on special request.

- The application areas of the product are versatile and range from conveying dust-free air to less aggressive, non-reactive gases or vapors.

- The exact temperature range can be found in the product data of the fans in the respective data sheets. As a general rule, the maximum continuous temperature of the fans is approximately 60 °C.

- The stainless steel version for the food industry is also available on request, where the speed is also fully controllable.

- Offshore applications of the axial fans in type stainless steel V4A for protection against salt water can be realized after consultation.

Click on the type designation in the overview for further product information.

Axial Fans Serie L

Axial Fans Serie K

Axial Fans Serie M

Axial Fans Serie G

Kaiser axial ventilators: Working principle and motor protection

A special feature of Kaiser axial fans are the asynchronous motors including an internal rotor, which were specially developed for fan construction. In addition, they are completely enclosed within themselves and surrounded by cooling fins on the outside. Good heat dissipation provides reliable protection against overheating, especially since the motor is located in the air flow of the fan. In addition, variable power is ensured by 100% speed controllability by means of special design measures, resulting in good efficiency to volume and pressure.

In the products, the motor is equipped with thermal contacts (TC). These products are temperature-dependent switching elements that are embedded in the motor winding in an insulated manner. The contacts in the fans provide better overheating protection compared to conventional bimetallic triggers because the replication of temperature conditions is more accurate. If the fans overheat, the TCs open an electrical contact and cause the fan to shut down. In the case of an AC motor, it switches on again automatically after cooling down, while in the case of a three-phase motor, a commercial circuit breaker is also connected upstream.

Characteristics

The characteristic curves of the fans (axial ventilators) are continuous. For this reason, the fans can be used in all characteristic ranges with larger air volume delivery, such as in

- ventilation and air-conditioning technology, in the form of wall fans in buildings

- in machine, apparatus and plant engineering,

- in refrigeration technology, e.g. as unit ventilators in heat exchangers.

The fans are available as standard in the type design as surface-mounted fans and built-in fans. Plate fans are available from 50 units/year.

Materials

Ball bearings of axial ventilators:

The products of axial fans have deep groove ball bearings with special clearance. Their type of bearings is permanently lubricated with a special ball bearing grease, which makes it possible to use them in the temperature range from -30°C to +180°C. A cold grease for temperatures below -30 °C is available on request. Furthermore, the type of bearing has a seal by means of two sealing washers. Spare ball bearings are available from the manufacturer by specifying the fan size.

Impellers of axial fans:

Since the fan bladesin the mold are made of heat-resistant plastic with fiberglass reinforcement, they provide high inherent stability. As a result, vibration noise occurs only to a minor extent. They are manufactured by plastic injection molding, which results in optimum profiling, which in turn enables the flow through the fan to be as linear and constant as possible. In combination with good motor cooling, high efficiency is achieved.

Protective grilles and steel rings of the axial ventilators:

For good corrosion resistance, the motors are coated with a protective paint layer after assembly. As standard, the discharge nozzles have an electrogalvanized or powder-coated finish; alternatively, a wet paint finish can be applied. The intake and discharge guards required for protection are also galvanized as standard. The latter are stamped in a special form from perforated plate according to CAD design in order to be able to ensure a higher load on the grilles of the fans. On request, the axial fans are available in the version of device fans.

The fans are equipped with a contact protection grille on the suction side according to DIN 24167 (contact protection against fan impellers). If a guard grille is required on the discharge side, it can be ordered as an accessory.

Stainless steel (stainless steel fans):

On request, we manufacture the fans in stainless steel grades V2A (WNr. 1.4301 or AISI 304 or X5CrNi189) and V4A (WNr. 1.4571 or AISI 316 or X10CrNiMoTil810).

Electrical connection

The axial fans each have a terminal box on the back of the motor. The electrical connection is made by means of terminal boards in the box. The cables are routed through IP 54 cable glands. Fans with AC motors are equipped with a run capacitor as standard, which eliminates the need for external mounting of the terminal box. The data of the electrical connection can be viewed in the Service section. Likewise, the setting of the fans can be found there. Products for the speed controllers can be found under Speed Control under Service Data.

Installation position and air flow direction

Each axial fan can be installed in any position. Since condensation can form in the motor in the event of large temperature fluctuations (min - max temperature), the motor is equipped with condensation drain holes on both end shields.

Installation position and air flow direction

Each axial ventilator can be installed in any position. Since condensation can form in the motor in the event of large temperature fluctuations (min - max temperature), the motor is equipped with condensation drain holes on both end shields. When ordering, the installation position should be specified in order to be able to fit holes correctly. Depending on the use of the fan, different air delivery directions are required. The profiled blades of the axial fan increase the efficiency in the main conveying direction. Therefore, it is also recommended to specify the air conveying direction when ordering.

If you have any questions about Kaiser axial fans, please feel free to contact us. Customer service is our top priority. We deliver quickly, directly and without costly intermediate stops.