All details [ liability-free ]

Please get further data from the data sheet:

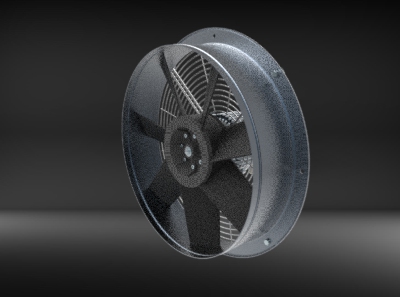

Axialfan KE254

The axial fan is also deliverable into high-grade steel and for the offshore use at a corresponding execution, see high-grade steel ventilators and offshore ventilators.

built-on ventilator

available from stock

built-in ventilator

available from stock

plate ventilator

available from 50 pieces

Description of KE254 axial fan

Axial fan type KE254 is an AC fan that runs very quietly. The fan with a nominal speed of 1400 rpm has a volume flow of 1200 m³/h and the fan has a diameter of 250mm. The overall size is therefore 250 mm.

The axial fans can be used for cooling small rooms, containers, generators and machines. As a built-in axial fan, the fan can be used in hall walls or office walls. When used in containers for cooling and ventilation, the stable mounting ring is helpful.

Voltage and control of KE254 axial fan

Due to the design as an AC axial fan, it can additionally be controlled steplessly via a temperature controller.

To improve the air quality in office rooms, an air quality controller can be used to control the fan. Axial fans can also be used for animal housing on organic farms.

To avoid damage to the motor at high temperatures, the use of thermal contacts in the form of bimetal switches is standard.

The rated voltage is 230Volt, 50Hz, but voltages of 110Volt, 60Hz and in three-phase operation of 480Volt, 60Hz (USA) and 575Volt, 60Hz (Canada) are also possible. Special voltages of 500Volt, 50Hz are also available.

Stainless steel versions of the KE254 axial fan

For the food industry we have developed the fans as stainless steel fans in V2A (material number 1.4301 or AISI 304 or X5CrNi189). Since high quality cast aluminum is used for the motors, they can be left raw for the food industry or painted with food color. The aluminum casting made of aluminum material approved for food industry is conceivable in the production, with higher annual purchase quantities.

For offshore applications, the fans can be manufactured in stainless steel V4A (material number 1.4571 or AISI 316 or X10CrNiMoTil810) for salty air.

In addition, painting with salt water resistant paint is possible.

Material of KE254 axial fan

Impellers are generally (standard) made of glass fiber reinforced plastic. Aluminum impellers are also available for higher temperatures.

The rectangular plate fan design is available by agreement. For cost reasons, however, this is only advisable from a minimum order quantity to be determined in advance.

The protection class is IP44, also available is IP54 and IP56 for humid environments.

By specifying the air direction when ordering, the installation position of the fans is fixed. However, this can be changed later without too much effort.

Technical diagram of the KE254 axial fan

The air direction of the axial fans is reversible, i.e. the air direction is reversible. The impeller blades are profiled for optimum efficiency (similar to aircraft wings), therefore in the reversed direction the air performance is reduced by about 15%.

The company Kaiser Ventilatorenbau has designed and developed the motors and specially made them for the axial fans. According to DIN EN 60085, the thermal protection class is F or H on request.

The bearing temperature has been tested via type tests. The operating temperature of the fans has also been verified in practical type tests. The stainless steel fans have been proven to be suitable for offshore use by means of salt water tests and an IPx6 humidity test.

The fan carries the CE mark and complies with the ERP 2015 Ecodesign Directive.

The motors are energy efficient and the fans comply with ERP2015 (ErP Directive 2009/125/EC EU Regulation No. 327/2011).

Since the fans are fully controllable, speed and power adjustment is possible over the entire power range. In the simplest case by robust multi-stage speed controllers in transformer design.

The KE254 axial fan with 230 volt AC motor can be controlled and regulated by stepless electronic speed controllers. Based on this, it is also possible to control our temperature controllers TR46 or C02 controllers and air quality controllers.

The three-phase motors can also be controlled by frequency converters. In accordance with DIN-IEC/TS 60034-17, it should be noted that, depending on the frequency converter, an all-pole sinusoidal filter must be connected between the motor and the fan.

Weather protection dampers and air outlet protection grilles are available to comply with the Machinery Directive.

STEP files in 3D CAD exchange format are available under the Service menu item and can be accessed at any time. These can be incorporated at an early stage in the design and construction process.

back to: Axial fans