All details [ liability-free ]

Please get further data from the data sheet:

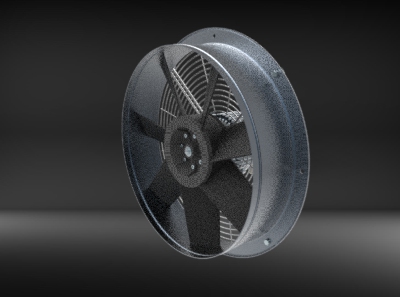

Axialfan KD352

The axial fan is also deliverable into high-grade steel and for the offshore use at a corresponding execution, see high-grade steel ventilators and offshore ventilators.

built-on ventilator

available from stock

built-in ventilator

available from stock

plate ventilator

available from 50 pieces

Description of the axial fan KD352

The axial fans of the KD352 series are three-phase fans in 2-pole design with a voltage of 400 volts, 50Hz. The higher speed of 2800 rpm results in high performance in terms of volume flow and pressure with a compact design. The impeller diameter is 350 mm, the nominal size is 350 mm.

The fan is used in all conceivable areas. Frequently for cooling of containers, the use with generators, machines, cooling of castings or forged parts. The design variant as axial built-in fan is preferably used in machine hall walls, office walls or walls in sandwich construction, for example in containers for machine cooling.

Voltage and control of the axial fan KD404

To protect the motor and in case of high temperatures, a thermal contact in the form of bimetal switches is installed in the winding of the fan as standard.

The voltage of the axial fan KD352 is 400V, 50Hz as standard. Other voltage frequency ranges such as 480Volt, 60Hz for USA and 575Volt, 60Hz for Canada can be manufactured. Special voltage of 500Volt, 50Hz can be supplied on short notice.

Stainless steel versions of the KD404 axial fan

In the field of stainless steel fans, the KD352A axial fan can be manufactured from V2A (material number 1.4301 or AISI 304 or X5CrNi189) and V4A (material number 1.4571 or AISI 316 or X10CrNiMoTil810).

The stainless steel grade V2A (material number 1.4301 or AISI 304 or X5CrNi189) relevant for the beverage and food industry (food industry) can be supplied. The motor housings are made of high-quality cast aluminum, so they can be left raw for the food industry or painted with food color. The aluminum casting made of aluminum material approved for food industry can be used in the production, with annual purchase quantities.

For the offshore area, this includes salty ambient air, as it occurs in the coastal area, on container ships or on drilling platforms, the stainless steel grade V4A (material number 1.4571 or AISI 316 or X10CrNiMoTil810) is used for the fans. The use of salt water resistant paint as the color of the motors can be used additionally.

Material of the KD404 axial fan

In addition to the standard impellers made of fiberglass reinforced plastic, the fan can also be equipped with aluminum impellers.

The plate fan with square cross-section can be supplied from a low minimum order quantity.

Protection class IP44 is supplied as standard. Other types of protection, such as protection IP54 and protection IP56, are available on request.

By specifying the direction of airflow, the installation position of the fans can be specified when ordering. If this is not done, it can be changed later without much effort.

Technical illustration of the KD404 axial fan

The direction of rotation of the axial fans is reversible, thus the air direction can be reversed, this is reversible. The impeller blades are profiled for optimum efficiency (similar to airplane wings), therefore in the reversed direction the air performance is reduced by about 15%.

The company Kaiser Ventilatorenbau has designed and developed the motors and specially made them for the axial fans. According to DIN EN 60085 the thermal protection class F or on request H is available.

By different tests in climatic chambers and humidity chambers the storage temperature and the temperatures possible for the operation have been tested.

With regard to the stainless steel fans, saltwater tests for the offshore sector and an IPx6 humidity test describing the usability are available.

The fan is built to be energy efficient and carries the CE- mark according to the Ecodesign Directive ERP2015 (ErP Directive 2009/125/EC EU Regulation No. 327/2011) and the Machinery Directive.

Full controllability of speed and power is provided by the use of transformer controller and frequency converter.

DIN-IEC/TS 60034-17 must be observed when controlling and using frequency converters. This describes that, depending on the frequency converter, an all-pole sinusoidal filter must be connected between the motor and the fan.

The product range also includes add-on parts such as weather protection dampers and air outlet protection grilles. The air outlet protection grilles are required in order to comply with the Machinery Directive for free-standing installations.

In the menu item Service, you will find the ready-made CAD data in STEP format required for your design. With their help, the fan can be integrated early in the design process of a plant. This saves time and costs by avoiding design changes.

back to: Axial fans