Kaiser KG as a fan manufacturer

Modern - Flexible - Customer-oriented" that is our motto.

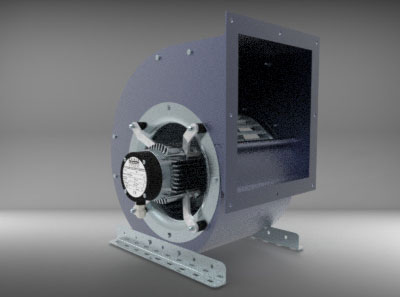

The company Kaiser Ventilatorenbau manufactures axial and centrifugal fans.

Our core competences are

- fast and direct deliverability without expensive intermediate stations

- high quality standard "made in germany

- constant further development in close cooperation with customers

- special solutions and consulting for customers

We also manufacture small series with special requests as well as single pieces.

Modern manufacturer of fans with a wide range of axial fans and centrifugal fans.

Digitalization Manufacturer Kaiser Ventilatorenbau

Introduction of first ERP system in 1995

In 1995 there were only a few ERP systems for medium-sized businesses. It was decided at that time to program an own ERP system on MS Office basis.

Web presence 1996

As a manufacturer of fans, Kaiser realized the importance of the Internet at an early stage and responded with an extensive web presence.

CAD (Computer-Aided Design) - Implementation 2018

In 2018, the transition to digitalization began with the implementation of a complete new CAD system for design and data management. The aging older 2D system was completely replaced. Since in this context all drawings also had to be newly created and checked in 3D, together with material inputs and reference to the latest material data sheets as well as current DIN standards, a costly but necessary conversion on the way to digitization.

ERP (Enterprise Resource Planning) - Implementation 2019

In 2019, the implementation of a completely new ERP software for better processing of data from material procurement to warehousing and sales took place. The old ERP software we had programmed had to make way for security reasons. Since we pay very high attention to the area of company data and its protection, we have so far been spared from production downtime due to Internet viruses.

Server - Implementation 2020

Due to the progressive digitalization of the company with the help of CAD and ERP software, the requirements for data storage also increased, which led to the introduction of our own server systems. Cloud storage on the Internet is not yet an option for us for data protection and security reasons. This means that we can continue to produce and deliver even in the event of Internet problems.

Company internal conversions and expansions

2006 Structural expansion

During the expansion in 2006, the warehouse was greatly enlarged, the channel and laboratory test stand was rebuilt and modernized. Furthermore, new offices were created and built in a modern energetic and soundproof way.

Introduction of own company code in 2008

Already in 2008 the company Kaiser Ventilatorenbau as a manufacturer started to introduce a company code. It is about the cooperation with customers and suppliers, points like sustainability, but also human rights and valid German law according to BGB and StGB must be kept. Corruption and favors from suppliers are prohibited, as are favors to customers; transparency and honesty have been part of our standards for many years.

The German Pay Transparency Act (EntgTranspG): Equal pay for equal work was and is implemented at Kaiser Ventilatorenbau long before it was legally stipulated. In addition to a good working atmosphere, open communication also increases satisfaction and employee loyalty.

Cooperation with renowned testing laboratory since 2010

In 2010, cooperation with a renowned testing laboratory took place for ongoing investigations and documentation of the usability at different temperatures, tests regarding protection classes (IP system) and the salt water test for stainless steel fans.

Introduction of new standards system in 2012

In 2012, a ninth step was taken with the introduction of a dedicated system for implementing necessary DIN standards and the systematic use and continuous monitoring of compliance with DIN standards.

Examples of standards used → Winding temperature

Sustainability strategy 2016

Already in 2016, the fan manufacturer Kaiser started to introduce a documented sustainability strategy.

Three fields of action for sustainability were and are defined.

We assume our own responsibility for:

Nature, Climate Protection and Society.

Products and supply chains,

our employees and data protection.

1. national and international business travel is greatly reduced. An important building block for sustainability is the use of Microsoft Teams and Zoom to avoid unnecessary travel through online meetings.

Focus on circular economy: We pay attention to reuse and recycling of packaging, avoid unnecessary use of operating materials and heat almost climate-neutrally.

Offices were soundproofed and energy-optimized as part of the 2006 expansion. Furthermore, we reacted by building green areas to compensate for CO2 emissions.

We pay attention to the production of our suppliers from Germany and Western Europe, so we reduce unnecessary long deliveries from the Far East and can maintain the quality standard. We also avoid production in low-wage countries with poor environmental protection. This makes us independent of international difficult supply chains.

Privacy

Data protection

We attach great importance to data protection within the company, especially with regard to our employees, customers and suppliers. Names and data are only released in special cases and only with prior approval.

Fans Production Made in Germany

Fan manufacturer with a clear commitment to Germany as a business location

"made in germany" means for us not only to operate the administration in Germany, but to have a clear commitment to the location Germany. Development, administration and production have always remained in Germany in order to be as independent as possible from international suppliers. This helps us to be able to deliver quickly and to maintain our high quality standards. Changes in development thus flow immediately into production, administrative decisions are close to production, and the entire value-added process can be interlocked. We also attach great importance to the fact that our suppliers come from Germany and Western Europe in order to be able to intervene quickly in case of quality issues. Regular audits can thus be carried out in an environmentally friendly manner, avoiding long international journeys.

Fan production with voltages for non-European markets such as USA/Canada, South America, Asia and Africa.

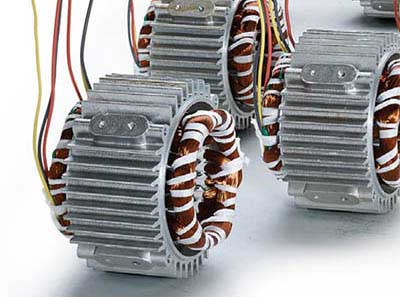

Due to the high vertical range of manufacture as manufacturer of the fans, starting from the motor to the impellers to the attachments, we can quickly realize requests for special voltages, even in small quantities.

As a manufacturer of fans, we can calculate and produce voltages for non-European markets such as the USA/Canada, South America, Asia and Africa at short notice.

These range from 480Volt, 60Hz over 575Volt, 60Hz up to 220Volt, 60Hz. Also multiple voltages of 400/690 Volt, 380/660Volt as well as 220/380 Volt are no problem for us, these are used for star-delta circuits.

Control by transformer, phase angle control as well as frequency converter (in compliance with DIN IEC/TS 60034-17) is possible.

Kaiser KG is a fan manufacturer Made in Germany

Our motors are in-house developments and are manufactured in our factory in Germany. The high vertical range of manufacture as a manufacturer enables us to quickly produce even smaller quantities with special voltages. The voltages vary from 480Volt, 60Hz over 575Volt, 60Hz up to 220Volt, 60Hz.

Multiple voltages of 400/690 volts, 380/660volts and 220/380 volts are possible....

Development and testing stainless steel fans through professional testingIn close cooperation with our suppliers, we have also included the fans in stainless steel (V2A and V4A) in the delivery program.

The use in different environments is not only determined theoretically, but also confirmed practically in tests in climatic chambers.

Salt water test procedures also show the possible use in the offshore area or in locations close to the coast. We have also demonstrated the corresponding IP x6. Temperature tests have confirmed the storage capability and use down to minus temperatures.

In addition, as a manufacturer, we also always adapt the fans to different requirements for our customers.

Development area:

We have our own CAD development in conjunction with our own measuring section to verify the calculated improvements in practice. Therefore, we have been able to continuously improve our fans and increase energy efficiency over the decades.

Development and production of axial fans with modern digital content

Manufacturer of axial- centrifugal fans

Our customers come from a wide range of industries, including Dax companies, MDAX companies, SDAX companies and TecDAX companies. We produce small series and single pieces, so there are also many customers from SMEs and family businesses among them.

The fields of application are diverse, including:

- Packaging machines,

- renewable energies,

- UV air purifiers,

- air conditioners,

- continuous casting machines, special machinery,

- crop protection laboratories,

- universities,

- food processing companies,

- drilling rigs...