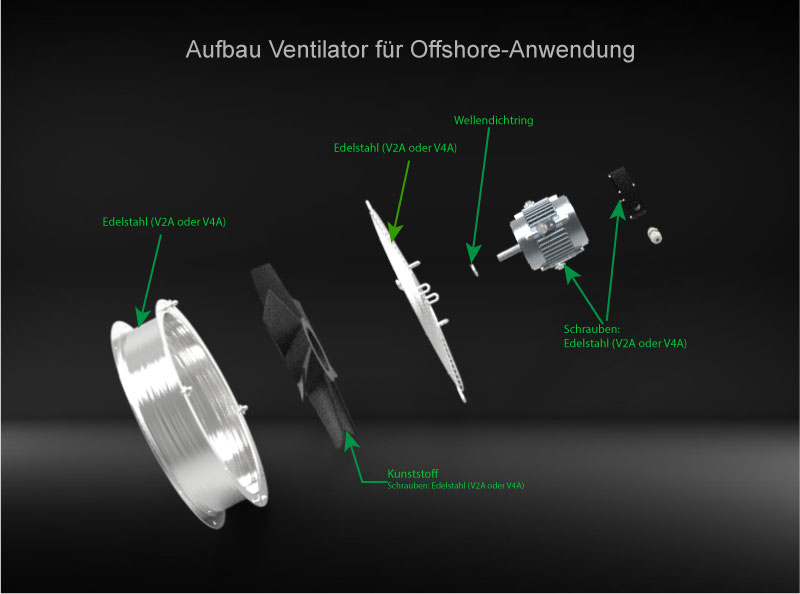

Offshore Fans (Ventilators)

A further special application area of the stainless steel fans is in the offshore area, since the V4A coating ensures good salt water resistance.

In addition, the motor can be painted with salt water resistance coating . An IPx6 protection can be achieved by the use of shaft seal rings.

Since the condensation water drains must be kept small or even completely avoided, large temperature fluctuations must be avoided. If these can not be prevented, protection against salt water must be ensured. Further seals in the area of the electrical connection are also provided.

There are model tests of the axial fans with regard to salt water resistance and increased degree of protection IPx6.

This design of the fans has been successfully running on platforms (oil riggs) for several years.

If you need these types of fans, we would be happy to advise you.

Corrosion of V4A steel in seawater conditions:

In the case of fans for the offshore sector, the corrosion resistance, in combination with sufficient strength, is of particular interest. The corrosion resistance of stainless steels is obtained by a thin passive layer on the surface. If this passive layer is missing, corrosion begins.

Intergranular corrosion occurs when chromium carbides precipitate at the grain boundaries. This can happen e.g. next to a weld seam. The seawater atmosphere causes intergranular cracks, which can lead to fracture. The metal is pulverized. The material 1.4571 is described as resistant to intergranular corrosion.

Not to get too deep into the choice of materials, it can be summarized from our experience in fan construction that the service life of the V4A steels we use is long enough in terms of corrosion to exceed the average service life expected by our customers for the fans under the extreme conditions.

Aluminum alloy of the engine casings:

The aluminum alloy we use in the casting of the engine casings is a

Eutectic alloy with excellent mold filling capacity, high hot cracking resistance and excellent casting properties with good chemical resistance, also to sea water.

As there is also good corrosion resistance with respect to seawater, the motors should be able to withstand the environmental conditions prevailing in the offshore sector without protective coating.

Of course, additional painting with seawater resistant paint is possible. As always, this depends on the service conditions and the expected service life.